Inscale’s Guide to Checkweighing Scales

Versatile and useful, checkweighing scales are some of the most popular weighing scales for industrial and commercial weighing applications. They aim to cut down time spent on repetitive weighing tasks and ensure uniformity in products, helping businesses save money and boost efficiency in the workplace.

This blog will give you a full insight into checkweighing, and will answer questions such as what is checkweighing and how it can be used to help your business thrive.

What is checkweighing?

Checkweighing is a process whereby a scale or balance is used to ‘check’ the weight of a subject to ensure they meet the required specifications and remain uniform in weight. A checkweighing scale, also often known as a checkweigher, is used in many instances, but is mostly found in packaging, production lines and shipping departments where the weight of subjects must be consistent. A good example of this would be weighing punnets of fruit, where each individual punnet would have to be uniform so that buyers receive the same amount of fruit per box.

How does checkweighing help businesses?

Checkweighing stock can save money, and help to ensure quality control which is instrumental in preventing inferior-quality products or goods from going out to customers. It is an excellent way to keep a hard-earned reputation is maintained, and a wide variety of applications can benefit greatly from checkweighing, including verifying package contents, establishing product tolerances, identifying parts, classifying products and checking for overload safety. For this reason a reliable checkweigher or checkweighing scale is essential to any business, small or large.

Businesses can use checkweighing to compare a product's weight against limits they have set, to determine if the weight falls within an acceptable range. If the weight is higher or lower than anticipated, they know something is amiss and can make the proper adjustments or corrections to achieve an acceptable weight.

An excellent reason to check-weigh products is to minimise or eliminate unwanted overfills or underfills. Workers can use then use the feedback provided by the results to make adjustments.

Checkweighing all packages can facilitate compliance with certain government regulations and industry standards. The market today is demanding, and 100-percent weight inspection is a critical factor in controlling quality and processes. Manufacturers that integrate successful checkweighing in their production lines can avoid costly fines levied as a result of inadequate or insufficient product content.

Checkweighing can verify that multi-packs and case shipments are not only correct, but also complete. It can be used to count packs and provide the total weight of boxes being loaded into a pallet, even determining the weight of each package. This helps ensure reliable product delivery, which leads to less hassle and ultimately, happy customers. if the product goes out right the first time, there is a reduce shipping and packaging costs associated with sending out additional items.

Who uses checkweighing scales?

Checkweighing scales are used in any environment that requires weighing results that are both accurate and consistent. They are commonly used for any operation that ultimately results in a finished product that will be sold commercially to customers.

Automotive/ Aerospace

Vehicle or machine manufacturers often use checkweighing scales that have been pre-programmed for check weight and check counting of machinery parts before assembly. Through checkweighing, automotive and aerospace engineers can detect whether a component or finished product has a defect or is missing components before distribution. Checkweighers can also be used for check counting tools, screws and other small parts that are easy to miss.

Construction

Construction materials such as concrete, brick and tiles are often checkweighed or counted before they are assembled to ensure the products are free from defects and comply with regulatory standards. Raw materials used in concrete are typically weighed according to a formula, therefore if you were weighing batches of concrete, a checkweighing scale could be used to pre-prepare the dry mixture into the correct quantities before adding water.

Within mass housing development projects, it is important to know the amount of materials workers have to work with. A checkweigher scale with check counting can be used to weigh a large amount of identical products such as tiles by assigning the weight of one tile as equal to one piece, allowing the operator to keep track of stock numbers as they are used without the need for arduous manual counting.

Distribution warehouses

In distribution warehouses, checkweighing scales are vitally important for ensuring that each product meets the weight specified on the packaging before it is sold commercially. The checkweighing process is usually assigned to the production line part of the distribution and manufacturing process in order to ensure each product passing through is of an identical weight.

Food processing

Similar to distribution warehouses, pre-packed food products such as biscuits and tins must be checkweighed on a trade certified scale that has been approved by your local regulatory authority to ensure that the product meets the weight value specified on the product label.

Do you need trade approved checkweighing scales?

Trade approved checkweighing scales are required for any industry that sells an item with a price that is directly related to weight. A good example of this would be when checking the weight of punnets of strawberries, which would be priced per gram, and so would require trade scales because the price is affected directly by the weight. Trade approved scales can be identified with a black M on the underside of the weighing scale or balance, although on older scales it may be green.

For a full guide to trade approved weighing scales and balances and to see which products require their use, please see our trade approvals guide.

Recommended checkweighing scales

Inscale stocks a wide range of checkweighing scales that can be used for a range of industrial and commercial applications:

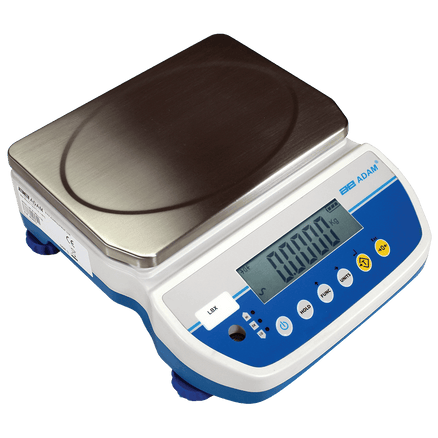

Adam LBX ‘Latitude’ Compact Bench Scale

Affordable and dependable, the LBX ‘Latitude range from Adam Equipment is simple to use and robust checkweighing scale that is perfect for food portioning, processing and general warehouse weighing. It boasts an impressive 240 hours of battery life meaning it can be used in areas without access to a mains power supply, and features a compact design making it perfect for weighing out smaller packages and containers.

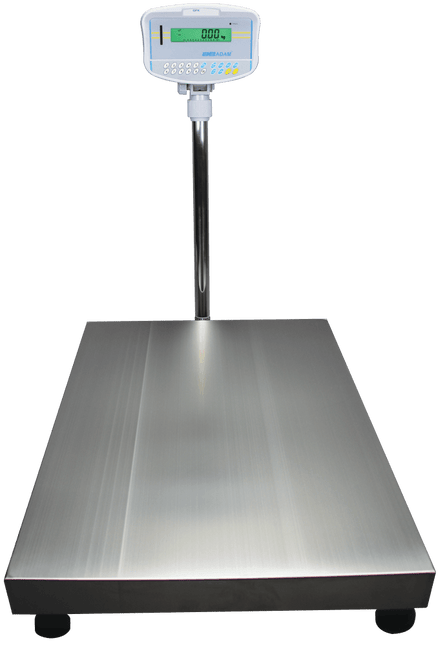

Adam GFK Checkweighing Floor Scale

The GFK range from Adam Equipment is a robust industrial checkweighing floor scale with an impressive 600kg maximum capacity. It features a large, stainless steel weighing pan that is perfect for weighing larger boxes and containers, making it great option for checkweighing applications in warehouses and dispatch departments. It features an easy to use numeric keypad for easy setting of high and low limits, as well as LED warnings when limits are reached. The GBK Mplus also comes with trade approved models if necessary.

Adam ‘Gladiator’ Waterproof Floor Scale

If a waterproof checkweighing scale is required for weighing in wet, humid or dusty environments, then we recommend the ‘Gladiator’ range. This is an IP67 rated waterproof scale with a grade 304 stainless steel weighing pan, meaning it can be wiped down or hosed down after use to ensure hygienic weighing practices. Because of this high level of protection, the Gladiator Waterproof Floor Scale is perfect for packaging and weighing out food and drink items. Trade approved models also available.

For any further information on checkweighing scales, please speak to a member of our team on 01908972660 or Get In Touch" rel="noopener noreferrer">Get In Touch.

Related blogs:

What to Consider When Buying an Industrial Floor Scale

Weighing Scales for Building Design & Construction

Using Counting Scales For End-of-Year Stocktaking

Leave a comment