The Right Counting Scale: Form vs. Function

Manually counting parts can be extremely tedious and prone to human error. The parts counting function on a scale helps improve this process and make it easier. There are two types of scales for this purpose – a counting scale and a weighing scale with a counting function. This blog will explain the difference and help you determine whether the right counting scale for you is even a counting scale at all.

What is Parts Counting?

Parts counting is a handy function built-in to a weighing scale or balance that uses weight to count pieces. For example, if you’re packaging washers to sell, you want to make sure that each box has the same number. Parts counting determines the average weight of one washer from a small sample. When you place a pile of them on the pan, your scale can divide the total weight by the average of one and provide you with an accurate count. That way, you can make sure that each box gets 50 washers without counting them manually.

Understanding Parts Counting Scales

Parts counting scales are scales intended to be used primarily for jobs and tasks like the one above. They offer a variety of unique features that make parts counting more convenient for those who use the application very frequently. We’ll get into those unique features more below.

Understanding Scales with a Parts Counting Function

Scales with a part counting function are ideal for those who primarily need a scale for weighing but from time to time may need to perform counting tasks. These scales offer parts counting to save you money – no need to buy a dedicated counting scale for those rare times you would need to use it. They’re typically more basic in operation, without as many additional features, if any, dedicated to smoothing the parts counting process.

Key Differences: Form vs. Function

Let’s deep dive into the true differences between parts counting scales and weighing scales with a parts counting function to help determine which one is right for you.

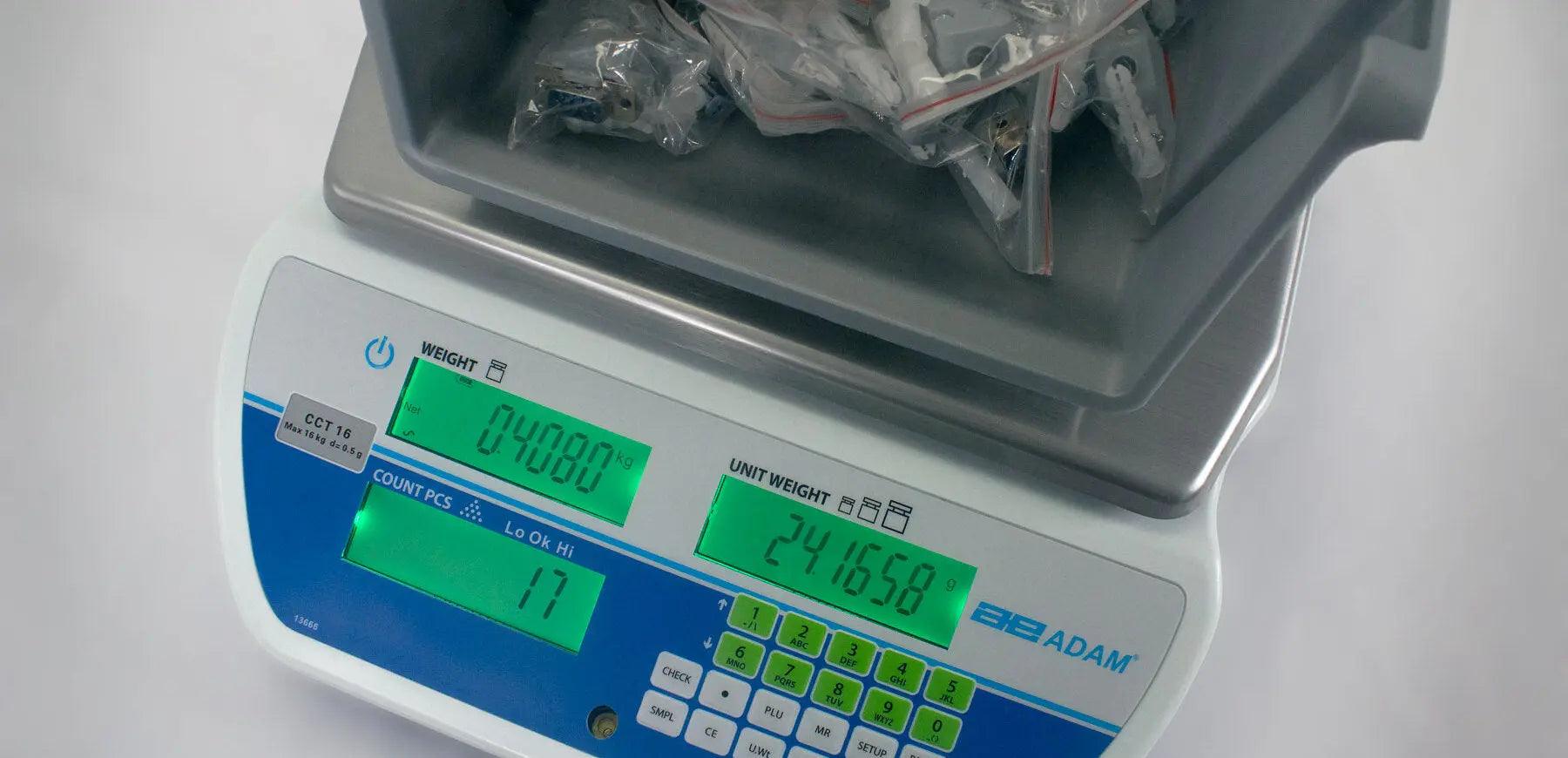

Count and Weight Displays

Counting scales offer three different displays, while non-counting scales only offer one. The three displays on a counting scale are for weight, unit weight and piece count. The unit weight is how much an individual piece weighs, weight is the total weight of the pile and piece count is obviously how many parts are present on the pan. This helps keep all this information distinctive and clear so you can make accurate records.

The weight, unit weight and piece count are all on one screen on a non-counting scale, which can occasionally get confusing if you’re not paying attention.

Accuracy and Precision

Whether or not counting and non-counting scales are accurate and precise isn’t in question – if they weren’t, we wouldn’t sell them. However, they can only do their best with your help, and we all know that human error is an unfortunate but common occurrence. For example, if you’re trying to count washers and you tell your scale that there’s a sample of ten on the pan when there are really eleven, your scale isn’t going to correct you. It’s going to give you results based on the incorrect information that you provided. In all reality, humans will never be free of error, but only counting scales will actively attempt to lower this risk, with the help of Product Lookups.

Product Lookups, AKA PLUs, are a memory system that allows you to store the unit weights of your most counted items. To enter a PLU, you assign a lookup number to the item so you can find it later. Then, you provide a sample as you normally would. Your scale stores the average weight of the pieces so that there’s no need to provide a sample when you want to count those items again. This significantly reduces the risk of human error, as the likelihood you’ll enter the wrong information increases the more often you do it. With a PLU, you’re one and done.

Ease of Use

Counting scales are built to make counting multiple identical items incredibly simple. Since parts counting can be a rather involved process, much of this simplicity stems from the buttons available on the display. Counting scales will often offer dedicated sample, unit weight and PLU buttons, along with a full numeric keypad. This way, you can start the process wherever you’d like – adding any number of a sample to determine the unit weight, inputting your own unit weight should you already possess the knowledge, or adding/recalling a PLU number.

On the other hand, weighing scales with a parts counting function prioritise the ease of normal weighing above all. To ensure that weighing is as uncomplicated as possible, there are usually fewer buttons. Those that remain are often multi-purpose. To access the parts counting function, it may require the strategic pressing of a few different buttons in a particular order. Once you’re in the right place, you don’t have as much flexibility. For example, the scale may require a very specific quantity of an item to get an accurate sample, instead of allowing you to provide a random amount.

Versatility and Flexibility

As we’ve established earlier, counting scales are going to be most useful for those that need to use it often. Though of course they offer regular weighing in addition to parts counting, for many, those are their only two purposes. Others may offer check counting, net total weighing or accumulation, functions that also involve a counting feature.

In contrast, a weighing scale with a parts counting function frequently provides additional applications. Others might include checkweighing, check counting, accumulation, percentage weighing, dynamic/animal weighing, and so on. They’re more versatile than counting scales in general.

Counting Scale Cost Considerations

Most scales that are geared towards a specific purpose, such as counting or checkweighing, will usually be a bit more expensive than a regular weighing scale with those functions.

For those who perform counting regularly, the right counting scale is an investment. Improved efficiency, reduced errors and convenience will save you money in the long run. For those who don’t count regularly, prioritising affordability is perfectly reasonable. Hitting a few extra buttons to reach the parts counting function a few times a month won’t impact your efficiency. In fact, your pockets will be happier without having had to invest in a counting scale for its occasional use.

Choosing the Right Counting Scale for Your Needs

Which counting scales and weighing scales do we recommend?

Counting Scales:

Cruiser CCT Bench Counting Scale

Capacity: 4kg – 48kg

Readability: 0.1g – 2g

Adam Equipment’s Cruiser CCT Bench Counting Scale offers an excellent internal counting resolution of 1:1,600,000, guaranteeing precise results. You can store and recall up to 140 PLU values to save you from spending time and energy repeatedly determining sample weights. For those who also require precise counting at a higher capacity, the CCT’s sister-product the Cruiser CDT Dual Counting Scale allows the scale to be connected to any Adam Equipment auxiliary platform.

BCT Label Printing Counting Scale

Capacity: 16kg – 300kg

Readability: 0.5g – 20g

Large businesses will love the BCT Label Printing Counting Scale with its extraordinary 1006 PLUs – you’ll practically never have to set a sample weight again! Easy-to-use software allows you to fully customise your label printings with weights, QR codes, bar codes and other components as you need. Perfect for labelling boxes after inventory counts and other similar applications.

A&D HC-I Precision Counting Scale

Capacity: 3kg – 30kg

Readability: 0.5g – 5g

A&D’s HC-i Precision Counting Scale not only offers 99 PLUs, but built-in Automatic Count Accuracy Improvement software. This software automatically corrects errors caused by variation in unit weights, which improves overall accuracy.

Scales with a Counting Function:

Aqua ABW-S Stainless Steel Waterproof Bench Scale

Capacity: 4kg – 32kg

Readability: 0.1g – 2g

Adam’s Aqua ABW-S Stainless Steel Waterproof Bench Scale is IP68 rated, perfect for dirty, messy, humid environments. It’s easy to clean and bacteria resistant. The Aqua Stainless can commonly be found in professional kitchens and harsh industrial environments. It offers a part counting function as a convenience, since you may not want to risk a non-IP rated counting scale getting dirty or wet.

Cruiser CKT Checkweighing Bench Scale

Capacity: 4kg – 48kg

Readability: 0.1g – 2g

The Cruiser CKT Checkweighing scale offers features to make checkweighing easier, rather than parts counting. The display changes colors, red, green and yellow if the results are above, within or under the limits you set. It offers a full numeric keypad to type in your limits, which can also be used to type in what sample you’re giving after pressing the dedicated sample button.

Capacity: 600kg – 6000kg

Readability: 200g – 2kg

The BFB Platform Scale by Kern is available for high-capacity counting when necessary. Extremely durable construction means the BFB can count large quantities of product without stress. This platform scale is IP67 rated for protection from splashes of liquid and dirt, for use in the messiest warehouse.

If you’re wondering what the right counting scale is for you, contact the Inscale team, we’ll be able to help.

Leave a comment